A Workflow of Auto Executing Services on SUSI.AI Smart Speaker

As we plan to create a headless client on RaspberryPi, the requirement was that the SUSI.AI programs should run automatically. To do so, we had to figure out a way to boot up various scripts on startup.

We had the following options to execute the scripts on startup:

- Editing Rc.local file

- Systemd Rules

- Crontab

We decided to proceed with Systemd Rules because using Rc.local and Crontab requires modifying the default system files which in case of any error would make the os functionalities to crash very soon.

We then created the SystemD rules for the following services:

1.factory-daemon.service

2. python-flask.service

3. susi-server.service

4. update-daemon.service

5. susi-linux.service

Now I’ll demonstrate the working and the functionality of each service being implemented.

1. Factory-Daemon Service

This service initiates the factory daemon with the raspberry Pi startup and then keeps it running continuously looking for any input from the GPiO port.

| [Unit] Description=SUSI Linux Factory Daemon After=multi-user.target [Service] Type=simple ExecStart=/usr/bin/python3 /home/pi/SUSI.AI/susi_linux/factory_reset/factory_reset.py [Install] WantedBy=multi-user.target |

2. Python-Flask Service

This service starts a python Server to allow handshake between mobile apps and the Smart Speaker which will allow the user to configure SUSI Smart Speaker accordingly.

| [Unit] Description=Python Server for SUSI Linux After=multi-user.target [Service] Type=simple ExecStart=/usr/bin/python3 /home/pi/SUSI.AI/susi_linux/access_point/server/server.py [Install] WantedBy=multi-user.target |

3.SUSI-Server Service

This service starts the Local SUSI Server as soon as the Raspberry Pi starts up which in turn allows the SUSI Linux programs to fetch responses of queries very quickly.

| [Unit] Description=Starting SUSI Server for SUSI Linux After=multi-user.target [Service] Type=oneshot ExecStart=/home/pi/SUSI.AI/susi_linux/susi_server/susi_server/bin/restart.sh [Install] WantedBy=multi-user.target |

4. Update-Daemon Service

This Service creates a Daemon which starts with the Raspberry Pi and fetches the latest updates from the repository from the upstream branch.

| [Unit] Description=Update Check- SUSI Linux Wants=network-online.target After=network-online.target [Service] Type=oneshot ExecStart=/home/pi/SUSI.AI/susi_linux/update_daemon/update_check.sh [Install] WantedBy=multi-user.target |

5. SUSI-Linux Service

This Service finally runs the main SUSI Linux software after everything has started.

| [Unit] Description=Starting SUSI Linux Wants=network-online.target After=network-online.target [Service] Type=idle WorkingDirectory=/home/pi/SUSI.AI/susi_linux/ ExecStart=/usr/bin/python3 -m main [Install] WantedBy=multi-user.target |

This blog gives a brief workflow of auto-executing services on SUSI Smart Speaker.

Resources

- Systemd Documentation: https://coreos.com/os/docs/latest/using-systemd-and-udev-rules.html

- Crontab Documentation: http://man7.org/linux/man-pages/man5/crontab.5.html

- RC.Local Documentation: https://www.raspberrypi.org/documentation/linux/usage/rc-local.md

Figure 1: UART Interface in PSLab

Figure 1: UART Interface in PSLab Figure 2: FTDI Module from

Figure 2: FTDI Module from

Surface mount components (SMD) are smaller in size. Due to this reason, it is hard to hand solder these components onto a printed circuit board. We use wave soldering or reflow soldering to connect them with a circuit.

Surface mount components (SMD) are smaller in size. Due to this reason, it is hard to hand solder these components onto a printed circuit board. We use wave soldering or reflow soldering to connect them with a circuit. Through Hole components (TH) are fairly larger than their SMD counter part. They are made bigger to make it easy for hand soldering. These components can also be soldered using wave soldering.

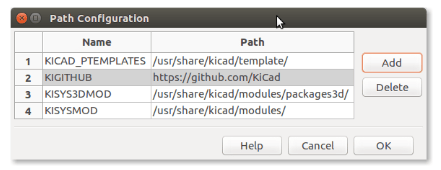

Through Hole components (TH) are fairly larger than their SMD counter part. They are made bigger to make it easy for hand soldering. These components can also be soldered using wave soldering. Go to “Eeschema” editor in KiCAD where the schematic is present and then click on the “BoM” icon in the menu bar. This will open a dialog box to select which plugin to use to generate the bill of materials.

Go to “Eeschema” editor in KiCAD where the schematic is present and then click on the “BoM” icon in the menu bar. This will open a dialog box to select which plugin to use to generate the bill of materials. Initially there won’t be any plugins available in the “Plugins” section. As we are adding plugins to it, they will be listed down so that we can select which plugin we need. To add a plugin, click on the “Add Plugin” button to open the dialog box to browse to the specific plugin we have already downloaded. There are a set of available plugins in the KiCAD installation directory.

Initially there won’t be any plugins available in the “Plugins” section. As we are adding plugins to it, they will be listed down so that we can select which plugin we need. To add a plugin, click on the “Add Plugin” button to open the dialog box to browse to the specific plugin we have already downloaded. There are a set of available plugins in the KiCAD installation directory.

The figure shows a HC SR04 ultrasound sensor. They are quiet famous in the electronic field; especially among hobbyists in making simple robots and DIY projects. They can be easily configured to measure distance from the sensor up to 400 cm with a measuring angle of 15 degrees. This angular measurement comes into action with the fact that sound travels through a medium in a spherical nature. This sensor will not give accurate measurements when used for scenarios like measuring distance to very thin objects as they reflect sound poorly or there will not be any reflectance at all.

The figure shows a HC SR04 ultrasound sensor. They are quiet famous in the electronic field; especially among hobbyists in making simple robots and DIY projects. They can be easily configured to measure distance from the sensor up to 400 cm with a measuring angle of 15 degrees. This angular measurement comes into action with the fact that sound travels through a medium in a spherical nature. This sensor will not give accurate measurements when used for scenarios like measuring distance to very thin objects as they reflect sound poorly or there will not be any reflectance at all.

You must be logged in to post a comment.